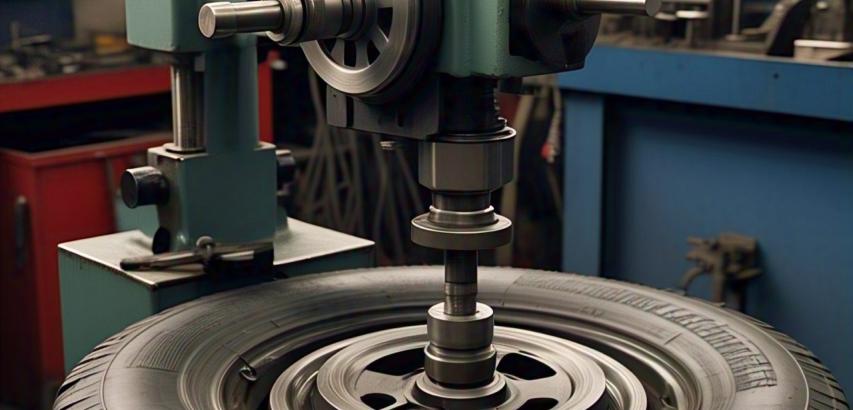

A Tyre Groover Machine is a specialized tool used in the automotive and motorsports industries for cutting or modifying the tread pattern of rubber tires. This machine is particularly useful in racing, off-road applications, or tire retreading industries where optimizing tire performance, improving grip, or extending tire life is essential.

Overview

The Tyre Groover Machine (also known as a tire grooving tool or tire regroover) uses a heated blade or cutting element to carve new grooves or deepen existing ones in a tire's tread. This allows technicians to modify the tread pattern for better traction, water dispersion, or handling characteristics, especially under specific track or weather conditions.

Key Components

Heated Blade or Element:

The core part that cuts into the rubber.

Heat reduces resistance and makes cutting smooth and precise.

Power Source:

Electric (most common), although some portable models may be battery-operated.

Temperature control is often adjustable.

Adjustable Cutting Head:

Allows control over groove depth and width.

Often includes interchangeable blades for various cut shapes (U, V, square).

Ergonomic Handle:

Designed for comfort and control during operation.

Types of Tyre Groover Machines

Manual Groovers: Basic models suitable for hobbyists or small workshops. Require more manual effort and skill.

Electric/Automatic Groovers: Offer consistent heat and precision. Ideal for professional use and high-volume work.

Industrial Tyre Regrooving Machines: Used in tire retreading plants for large-scale operations, especially with commercial truck tires.

Applications

Motorsports:

Adjusting tread for track conditions (wet, dry, dirt, etc.)

Customizing tires for improved cornering or straight-line performance.

Off-Roading:

Enhancing grip on loose or rugged terrain by modifying stock tread.

Retreading Industry:

Deepening worn-out commercial vehicle tires to extend usability.

Economical and eco-friendly alternative to new tire production.

Agriculture & Construction:

Custom grooves on tractor or heavy equipment tires for specific field conditions.

Advantages

Enhances tire performance based on application.

Extends the life of existing tires.

Reduces the cost of purchasing new tires.

Allows customization for specific racing or terrain needs.

Safety and Precautions

Always ensure proper ventilation due to rubber fumes.

Wear protective gloves and eye protection.

Never groove tires with structural damage or sidewall wear.

Only trained personnel should perform regrooving, especially on road-use tires, as improper grooving may compromise safety or legality.

Legal Considerations

In many regions, regrooving is not allowed for passenger car tires but is permitted for commercial truck tires if marked "Regroovable."

Always check local and international tire safety regulations before modifying any tire.

|  |  |